Custom RC Model Strandbeest

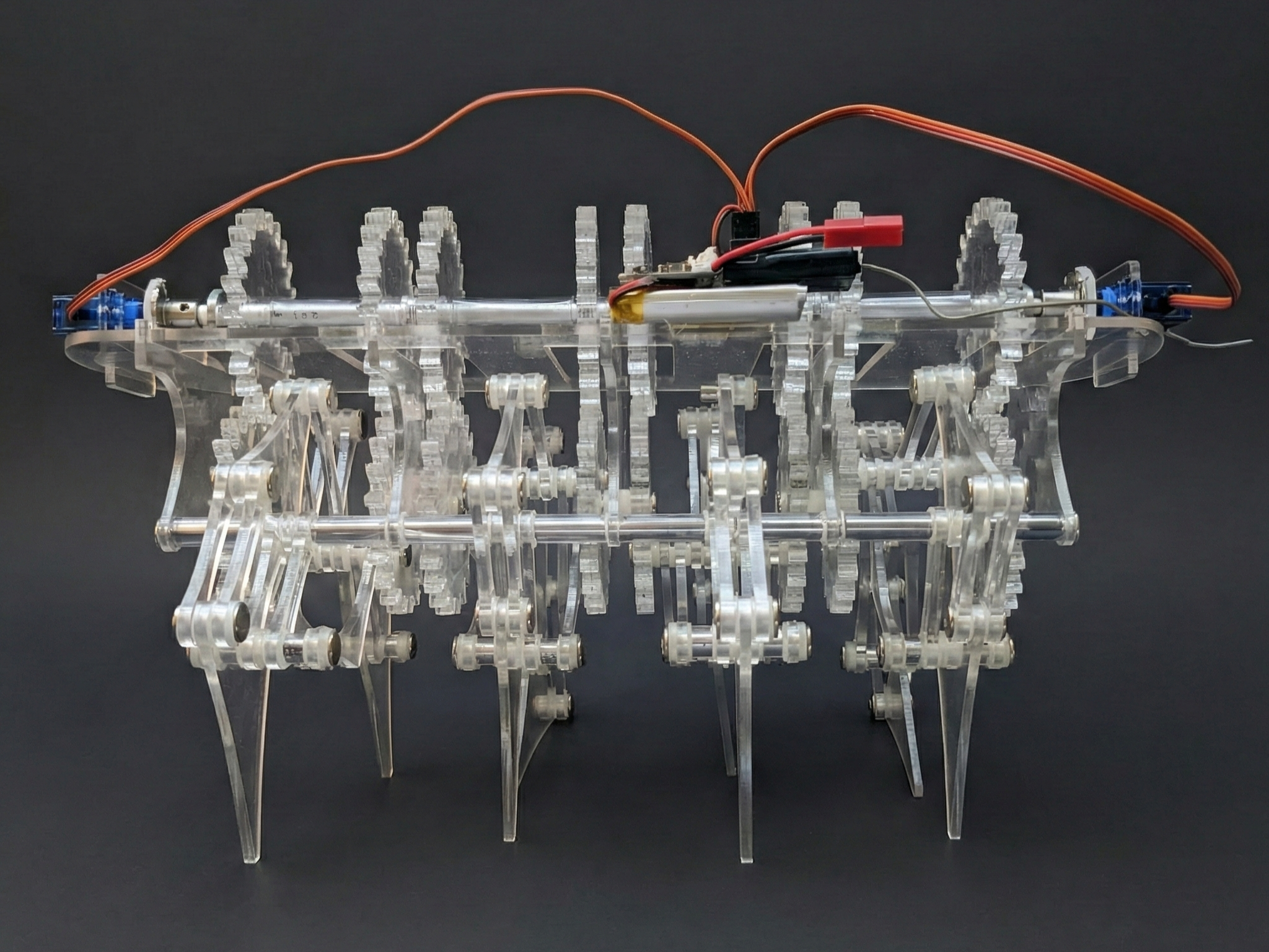

Personal RC walking robot inspired by Theo Jansen’s strandbeests.

Skills Demonstrated

- Kinematic linkage design and gait evaluation for walking mechanisms.

- CAD motion studies and drivetrain planning in Fusion 360.

- Precision fabrication and assembly of large multi‑part acrylic mechanisms.

What (Problem & Context)

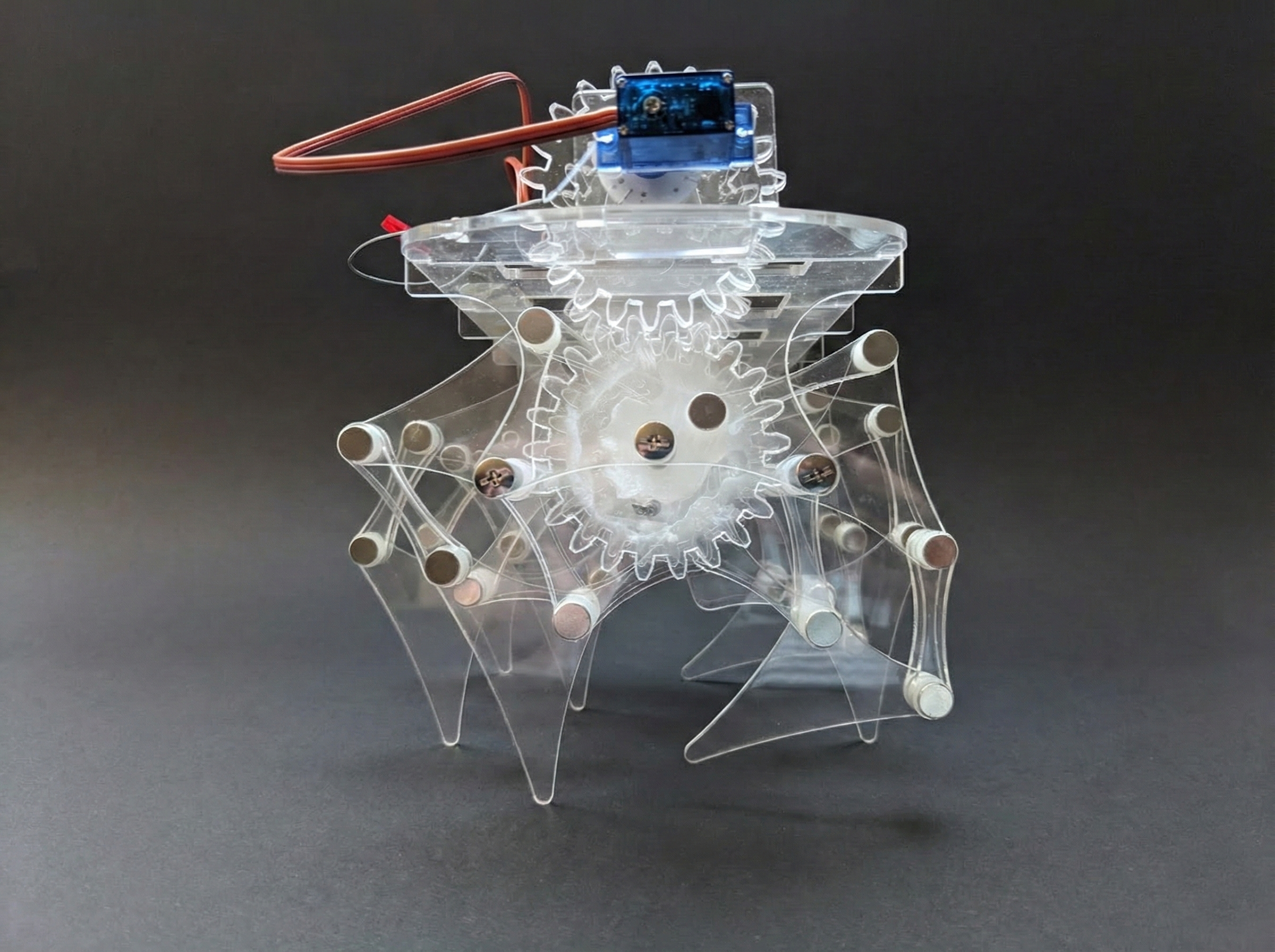

- Goal: free‑standing walker that can go forward/backward and turn in place.

- Context: personal design project (not a class or team assignment).

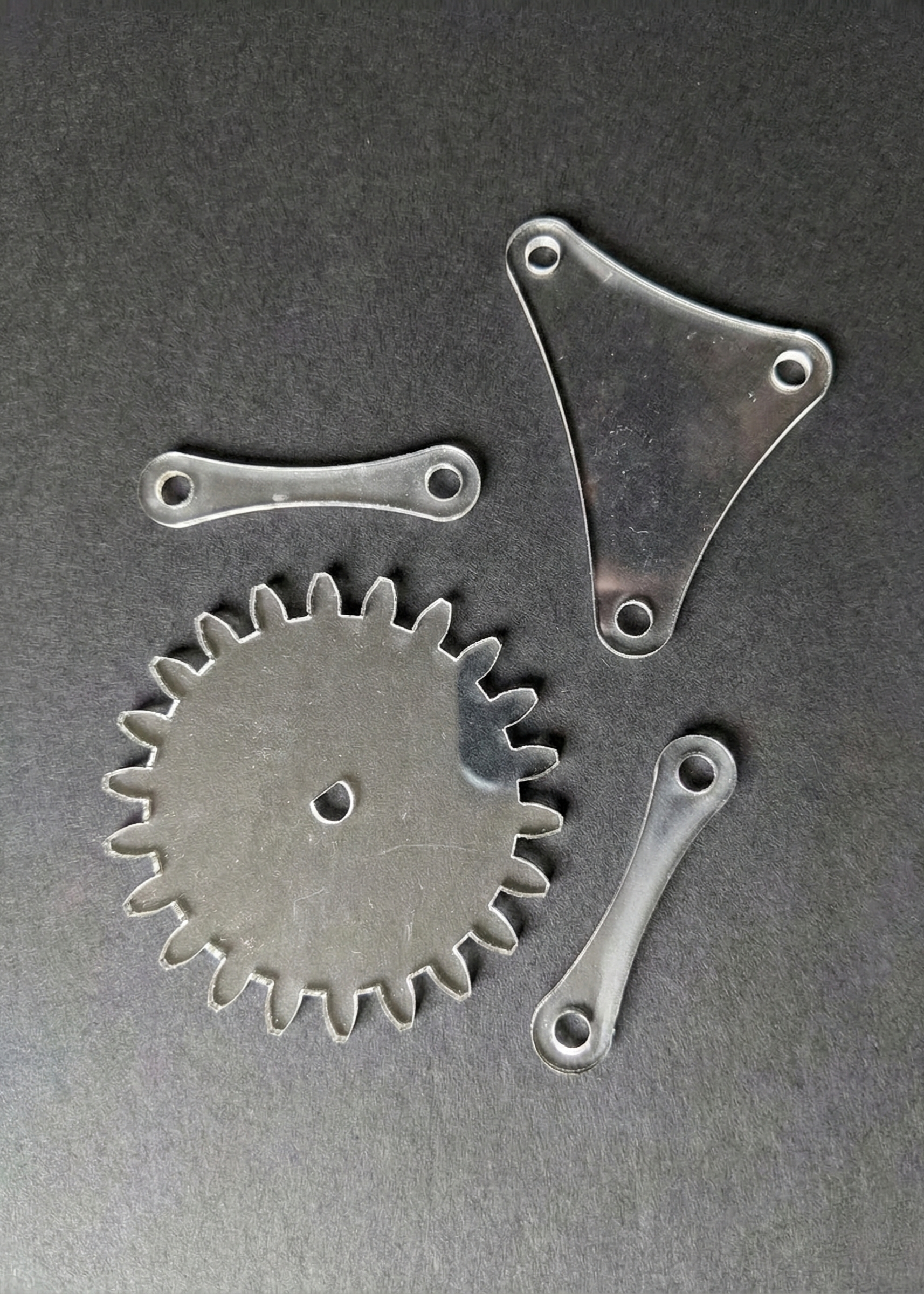

- Why it was hard: convert Jansen’s linkage into a reliable, compact, manufacturable drivetrain with stable ground contact.

How (Process & Constraints)

- Designed four pairs of legs in Fusion 360 using Jansen’s linkage proportions.

- Drive architecture: each leg pair on a common gear; two pairs per D‑profile axle.

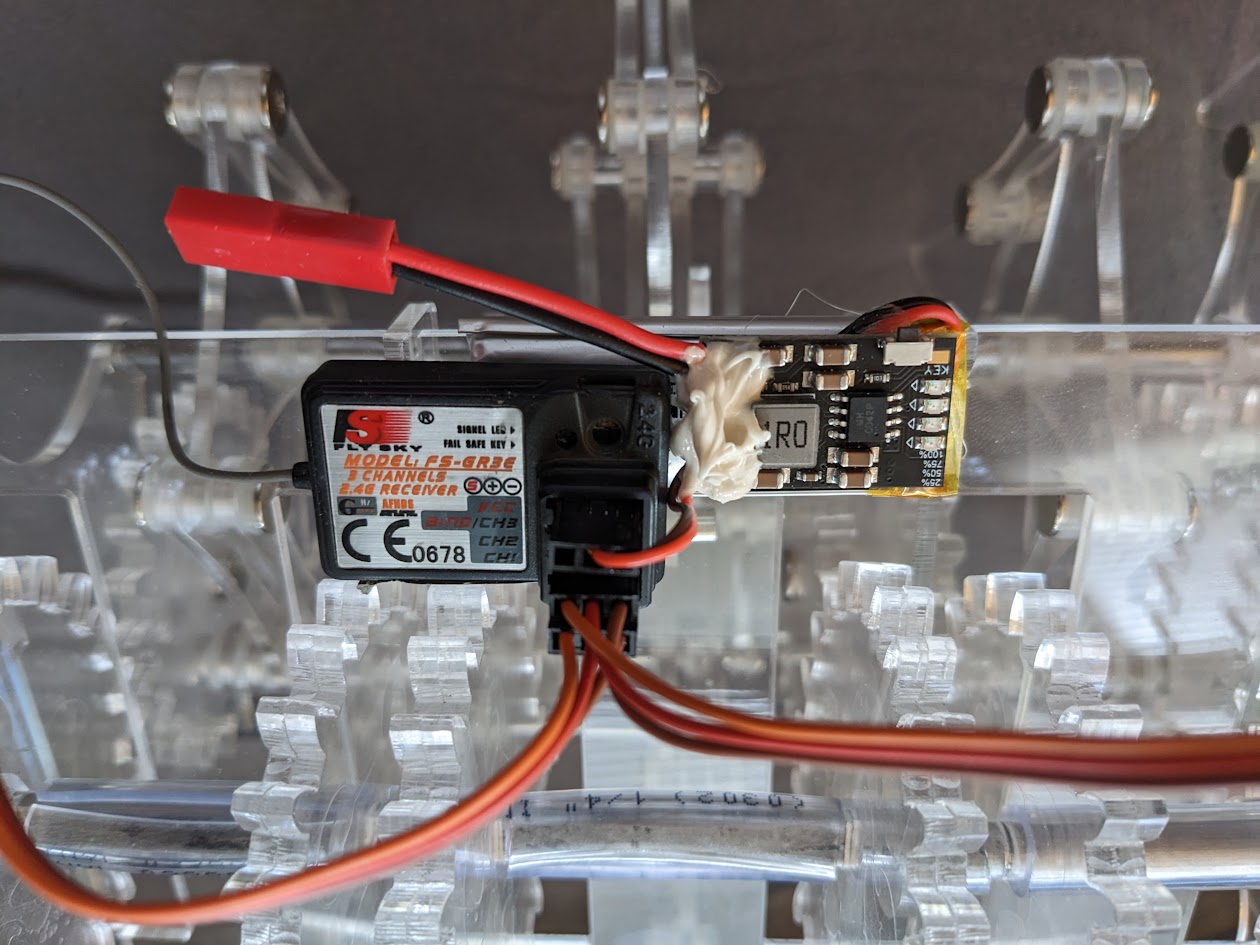

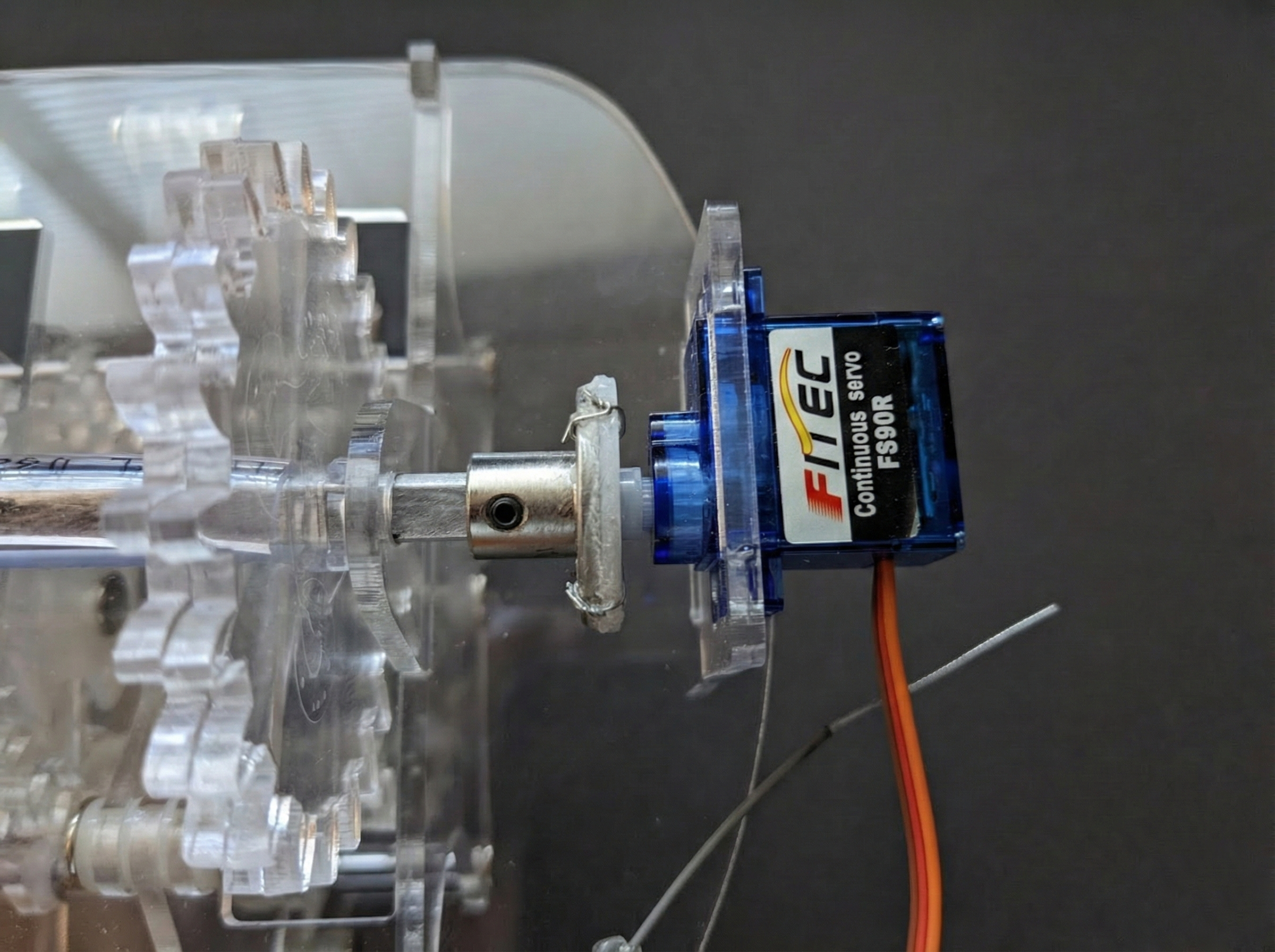

- Actuation: two 5V continuous‑rotation servos for differential drive.

- Simulation: rigid‑body kinematics with joint constraints to validate gait stability.

- Gait tuning: leg pairs offset to keep at least half the feet on the ground.

- Fabrication: 300+ acrylic parts (12 gait components) from 3mm cast acrylic.

- Workflow: DXF nesting in Deepnest, 50W CO2 laser cutting, iterative assembly/testing.

- Constraints: acrylic tolerances, joint friction, planar alignment, compact drivetrain.

Why (Results & Impact)

- Achieved stable, independent leg motion and controlled turning via differential drive.

- Validated a full design‑to‑fabrication pipeline for complex linkage systems.

- Strengthened skills in kinematic modeling, simulation‑driven design, and precision assembly.

Team & Contribution

- Individual project: owned full scope from concept through assembly and testing.

- Responsibilities: linkage design, motion‑study validation, drivetrain design, fabrication.

Challenges & Fixes

- Issue: friction and binding at pin joints from planar misalignment.

- Fixes: carriage bolts with Loctite, nylon washers, latex tube spacers, lubrication.

- Result: reduced friction enough for 5V servos to drive the full mechanism.

Media